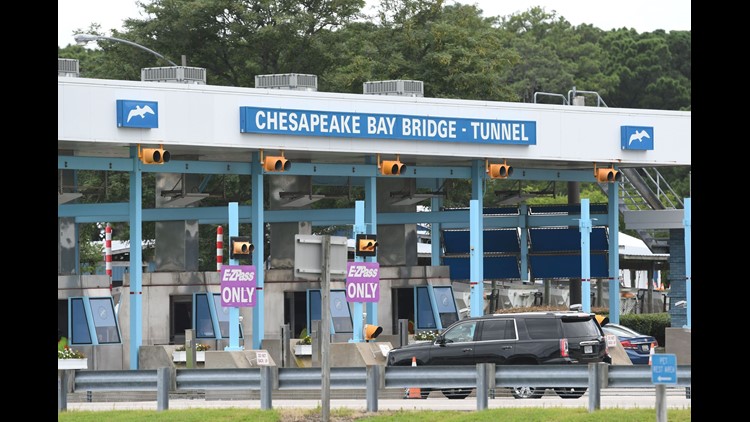

THIMBLE SHOAL CHANNEL, Va. (Delmarva Now — Judging from the questions asked during a recent tour, people are interested in even the most esoteric details of a parallel tunnel construction project underway on the Chesapeake Bay Bridge-Tunnel.

Around 200 people — four busloads, two starting from each side of the bridge — got to take the free tour offered on Aug. 3 — and there were plenty more people on the waiting list, an official said.

"We want you to walk away today as informed as you can be," said executive director Jeff Holland.

The facility typically offers tours to between 750 and 1,000 people a year, "in the interest of transparency," Holland said.

With the new tunnel project, interest is high.

Participants in the nearly two-hour tour got a brief history of the facility from Holland, as well as an up-close look at work going on in preparation for building a second, one-mile-long, two-lane tunnel under Thimble Shoal Channel, as the buses drove the length of the bridge-tunnel a couple of times.

The tunnel will be built using a special tunnel boring machine built in Germany. The machine was nicknamed "Chessie" after a naming contest for middle school students in the region.

Nandua Middle School student Grace Bentley submitted the winning name.

Construction on the tunnel project officially started Oct. 1, 2017, after a groundbreaking ceremony in September, and it is estimated the project will be completed in fall 2022, at a projected cost of nearly $756 million.

When completed, the new tunnel will carry two lanes of traffic southbound and the existing tunnel will carry two lanes of traffic northbound.

"We are hopefully driving cars through it in 2023," said Ryan Banas, construction manager with HNTB Corporation of Virginia Beach.

The project will be paid for through the sale of toll revenue bonds, loans, and money from the District’s general fund.

The Chesapeake Bay Bridge-Tunnel District receives no subsidies.

"So, it's entirely funded by tolls, by the lease revenue we derive from 37 industrial waterfront acres we own in Virginia Beach, as well as interest income on our investments," said Holland.

The top of the completed 42-foot diameter tunnel at its maximum depth will lie 105 feet below the water surface.

"When you are driving down there, your tires will be 135 feet below the water," said Banas.

PHOTOS: Chesapeake Bay Bridge-Tunnel construction tour

A planned dredging project to take the Thimble Shoal channel to a depth of 55 feet, in order to accommodate today's larger ships, will work out with the depth below the surface of the new tunnel as well as of the existing tunnel, according to Holland.

"You may wonder, do we have that capacity? We do. What we are doing for additional protection, (is) prior to the actual channel dredging, both to the east and to the west of the existing tunnel, we are doing a hardening project over our existing tunnel," he said.

That involves removing a combination of fill and small rock and replacing it with either a concrete blanket or rock, depending on which technical concept is decided on.

That process will last from 2019 to 2026, coinciding in part with the new tunnel construction "not by design, but just in sheer coincidence," Holland said.

The boring process is one that has not been used for transportation tunnel building in the region in the past — although in Europe and Asia, 70 percent of tunnels now are built using boring machines, according to Holland.

"It's the first time for a transportation bored tunnel in the Mid-Atlantic area of the United States," he said, adding, "Just yesterday, the Hampton Roads Bridge-Tunnel ... announced that they have decided they are going to follow our lead with the tunnel boring machine being the method that their contractors would actually utilize" for a planned parallel tunnel project there.

The boring process reduces the environmental impact of the project compared to other construction methods, and also has less impact on shipping and boat traffic, according to officials.

Once it gets underway, the boring machine will advance about 50 feet a day.

"You're building the sections to sections to sections, and the initial part that they are jacked against is a launching jack that you will be able to see if you come out for the launching ceremony," Holland said, adding,"So the launching section is actually reinforced extensively to make sure there is no movement, and that's where the initial rings are started, and after that, it's a cyclical process," Holland said.

A launching ceremony for the boring machine is planned for 2019, after the machine arrives from Europe.

Factory acceptance testing for the machine was completed in July.

The segments that make up the tunnel's rings are 18 inches thick, steel fiber-reinforced concrete, made to last 100 years.

Each ring is made up of 10 concrete segments, each of which is 20 feet wide and weighs 20,000 pounds.

The segments will be made in Chesapeake, Banas said.

The tunnel will be built of about 9,000 individual concrete pieces, using about 42,000 cubic yards of concrete.

The boring machine will remove about 500,000 cubic yards of soil in the process.

Once underway, 20 to 25 people will work around the clock in two, 10-hour shifts, along with a four-hour maintenance shift, Holland said.

Tour participants got to see crews at work on building the launching pit for the boring machine, one of the first stages of the tunnel project.

"That launching pit, in and of itself, is a massive overall island works project," said Holland.

The landscape of the manmade island where the pit is being built will change in the coming months.

"Next year, if you guys were to come out here, right beneath us you would be in the launch pit of the tunnel. You would be about 40 to 50 feet lower than you are right now," Banas told participants as the bus stopped for a closer look.

Once the pit is ready, the boring machine will be lowered into it so tunneling can begin.

"They can take that tunnel boring machine off of a temporary dock that will be built out here to our right, swing it over in place, lower it down, reassemble all of those parts coming over from Germany, and start pushing out into the Bay," Banas said.

One question on some people's minds on the tour was about whether the completed facility will include a restaurant, as it did in the past.

That is not going to happen, Holland said.

"The reason is, the island expansion is very, very costly. We wanted to have a restaurant and retail facility that was going to be approximately two to three times the size of what we had. We went out and got prices — to be able to do that was going to be $1 billion."

Given that the purpose of the facility is transportation, not food service or retail, it was decided to re-scope the project without those amenities to achieve a lower price tag, he said, adding, "We wanted to make that we were able to separate need from want."

Once that was removed, the low price came in at $756 million, meaning accommodating a restaurant and store would have cost an additional $250 to $260 million.

"It would be the most subsidized food operation in the world," Holland said.

Still, a fishing pier that was a popular feature on the island will be reconstructed and will be open to the public once the project is completed.

"While we might not be able to feed you dinner, you can at least catch your dinner out here," quipped Banas.

Information about the tunnel project is at http://www.cbbt.com/project-description/